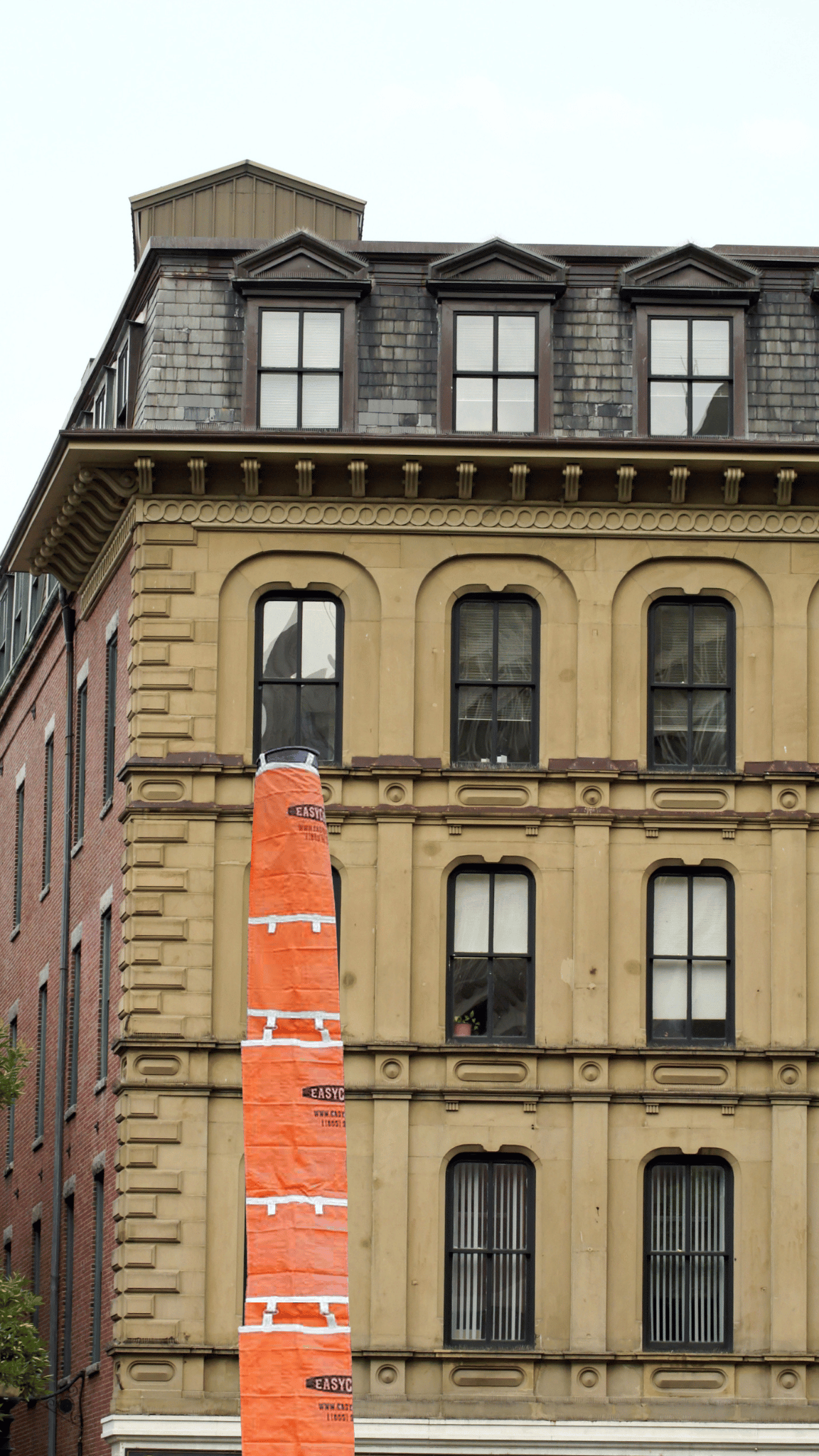

Trash Chute Job Site: Efficient Waste Management Solution

Safety and Durability

Trash Chutes: Ultimate Solution for Construction Debris Removal

Reasons to Choose a Trash Chute System

Trash chutes offer a plethora of advantages for construction sites. From improving safety to streamlining debris removal processes, here are some key reasons why you should consider incorporating a trash chute method into your projects:

Safety

One of the most critical advantages of using a rubbish chute methods is the enhanced safety it provides at the construction site. By offering a designated and secure opening for debris disposal, garbage chutes significantly reduce the risk of injuries caused by debris falling from heights. With proper installation and regular maintenance, you can create a safer working environment for your crew.

Durability

Trash chute systems are typically constructed from high-quality materials such as stainless steel or impact-resistant plastic. These durable materials ensure that the rubbish chutes can withstand the daily wear and tear of construction work. By investing in a durable rubbish chute methods , you can enjoy long-lasting performance and reliability throughout your project.

Convenience

Having easy access points on each floor of a building, trash chutes eliminate the need to manually transport debris down multiple flights of stairs or elevators. This convenience saves precious time and effort for your crew, allowing them to focus on more critical tasks at hand. With a rubbish chute system in place, waste removal becomes a seamless and efficient process.

Efficiency

Trash chutes facilitate the quick and organized disposal of waste, helping to keep the work areas clean and clutter-free. By using a trash chute system, you can ensure that debris is promptly removed from the site, preventing potential delays or disruptions to your project timeline. The efficiency provided by trash chutes can ultimately lead to cost savings and improved project productivity.

Cost-Effectiveness

While the initial investment in a trash chute process may seem daunting, the long-term cost-effectiveness cannot be ignored. By reducing the time and labor required for debris removal, a rubbish chute system ultimately saves you money in the long run. Additionally, the increased safety and productivity provided by a rubbish chute system can lead to a quicker project completion time, further saving you money on labor costs.Environmental Impact

In today’s environmentally conscious world, minimizing waste and reducing our carbon footprint is more important than ever. A trash chute method can help you do your part by ensuring that waste is disposed of properly and efficiently. By keeping your work site clean and organized, you can contribute to a more sustainable construction process.Reduced Risk of Injury

Carrying heavy debris up and down stairs or across uneven terrain can be a recipe for disaster when it comes to workplace injuries. By using a trash chute system, you can significantly reduce the risk of strains, sprains, and other injuries caused by manual lifting and carrying. This not only protects your workers but also helps to minimize downtime due to injury-related absences.

Choosing the Right Trash Chute System for Your Construction Project

Construction projects involve several important aspects that need to be considered carefully. Selecting the right rubbish chute system is one such aspect that is often overlooked. A poorly chosen chute system can impact the efficiency and safety of the entire construction site. This article will help you understand the key factors to consider when selecting a trash chute method for your construction project.

Length

One of the first considerations when choosing a garbage chute system is the length of the chute. The length of the chute will depend on the height of the building and the distance that the debris needs to be transported. It is essential to ensure that the chute is long enough to reach the ground level safely and efficiently.

Chute Section Material

The material of the chute part is another critical factor to consider. The chute section material should be durable and able to withstand the weight and impact of debris. Stainless Steel and polyethylene are common materials used for chute sections, each with its advantages and disadvantages.

Safety Features

Safety should always be a top priority on any construction site. When choosing a rubbish chute method , look for features such as safety locks, emergency stops, and debris deflectors to ensure the safety of workers and passersby.

Duraflat Chute

Ideal for roof work or renovation projects, the Duraflat chute features a flat design that allows for easy installation and removal of debris. This type of chute system is convenient for projects where space is limited and access to the roof is restricted.

Durachute Roof System

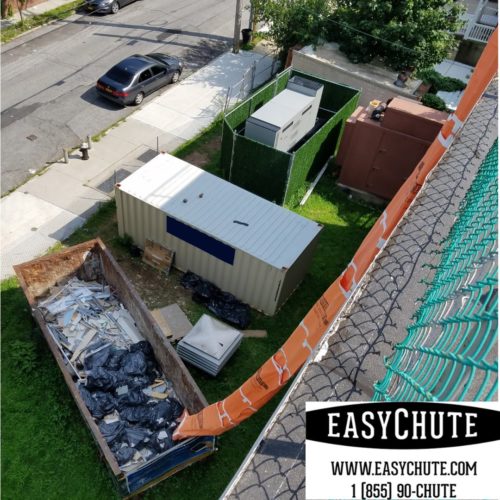

Designed specifically for rooftops, the Durachute roof chute system provides a secure and efficient way to transport debris from the roof work to ground level. This system is ideal for high-rise buildings or projects where debris needs to be quickly and safely removed from the rooftop.

Polyethylene Chute

Polyethylene chutes are lightweight yet durable, making them an excellent choice for construction projects of all sizes. These chutes are easy to install and transport, making them a popular option for many construction companies.

Trash Chute System Installation and Maintenance

It is crucial to have a professional team handle the job. Our experienced technicians are well-versed in all aspects of installing and setting up a garbage chute system for residential or commercial buildings. From selecting the right location for the chute to ensuring proper ventilation and safety measures, we take care of every detail to guarantee a seamless installation process.

Location Selection

Choosing the ideal location for the trash chute is crucial for ensuring convenience and ease of access for residents or employees. The placement of the chute should be strategically planned to minimize the distance residents need to travel to dispose of their trash. Additionally, the location should be easily accessible for maintenance and cleaning purposes. By carefully considering the placement of the trash chute, you can enhance the overall functionality and efficiency of the system.

Ventilation

Proper ventilation is key to maintaining a clean and odor-free environment within the building. Inadequate ventilation can lead to the accumulation of unpleasant odors and the growth of bacteria and mold. When installing a garbage chute system, it is essential to ensure that adequate ventilation is provided to prevent these issues. Proper ventilation not only improves air quality but also contributes to a more hygienic environment for residents or employees.

Safety Measures

When installing a trash chute process, safety should be a top priority. Incorporating safety features such as fire-rated doors and locking mechanisms can help prevent accidents and ensure compliance with building codes. Fire-rated doors are essential for containing smoke and flames in the event of a fire, while locking mechanisms prevent unauthorized access to the chute. By implementing these safety measures, you can create a secure and hazard-free environment for building occupants.

Cleaning

Regular cleaning of the chute and hopper is necessary to remove debris and prevent clogs. Accumulated trash can lead to blockages and malfunctions in the system, compromising its efficiency. By scheduling routine cleaning sessions, you can maintain the cleanliness and functionality of the trash chute. Additionally, proper cleaning practices can extend the lifespan of the system and prevent costly repairs in the future.

Lubrication

Applying lubricants to the moving parts of the garbage chute system helps maintain smooth operation and prevents wear and tear. Over time, friction and debris can cause parts to become worn out and result in system malfunctions. Regular lubrication of the chute components can reduce friction, extend the lifespan of the system, and ensure optimal performance. By incorporating lubrication into your maintenance routine, you can keep the trash chutes functioning smoothly for years to come.

Inspections and Repairs

Regular inspections are essential to check for any signs of damage or malfunction in the trash chute process. Identifying and addressing issues promptly can prevent minor problems from escalating into major repairs. Trusting a professional service provider to conduct routine inspections can help safeguard the integrity and efficiency of the system. In the event of any repairs or maintenance requirements, prompt action should be taken to ensure the continued reliability of the trash chute.

fStreamlining Construction Debris Management with Trash Chutes

In the bustling world of construction sites, efficiency is paramount. Every element, from material delivery to waste removal, must be optimized to keep projects on track and budgets in check. Among the many solutions available, one often overlooked yet invaluable asset is the trash chute. These discreet yet powerful tools streamline debris removal, ensuring a clean and safe work environment while maximizing productivity.

Simplifying Waste Disposal

At the heart of any job site, stainless steel construction debris chute process stand tall as indispensable conduits for waste removal. These chutes, composed of durable steel construction, offer a reliable solution for transporting construction debris from the upper floors to the ground level with ease. Their versatility allows them to handle a variety of materials, from heavy construction waste to smaller scraps, efficiently.

The Anatomy of a Trash Chute

A typical trash chute consists of several key elements. The chute sections, often made of stainless steel or high-density plastic, form the main conduit for relics disposal. Their edge length and diameter are meticulously designed to facilitate smooth flow while ensuring durability. At the bottom, renovation options such as floor debris chutes or durachute roof products provide flexibility in disposal methods, catering to diverse construction needs.

Durability and Reliability

When selecting a debris chute system, factors such as durability, weight, and ease of use come into play. Trash chute renowned provider in the market, prioritizes quality and longevity in their products, offering solutions that withstand the rigors of construction sites. With a commitment to excellence and a focus on customer satisfaction, their chute process ensure seamless operation throughout the project lifecycle.

Efficiency in Action

The advantages of implementing a garbage chute system are manifold. Not only do they expedite debris removal, but they also enhance safety by minimizing clutter and debris on-site. Moreover, their sleek design and efficient operation make them a preferred choice for construction professionals seeking to optimize workflow and minimize downtime.Beyond Construction

While commonly associated with construction sites, trash chutes find utility in various other settings. From renovation projects to demolition sites, their versatility makes them indispensable tools for waste management. Moreover, alternatives such as dumpsters or manual removal pale in comparison to the efficiency and convenience offered by well-designed garbage chute systems.Addressing Common Concerns

Despite their efficacy, trash chutes may present certain challenges, such as size limitations or debris blockages. However, with proper maintenance and adherence to safety protocols, these issues can be mitigated effectively. Regular inspections, prompt repairs, and clear communication among site personnel are essential to ensuring the uninterrupted operation of trash chute methods.Significance of Trash Chutes on Job Sites

In construction, where every minute and movement counts, the incorporation of garbage chutes revolutionizes waste management strategies. These unassuming yet essential systems offer a seamless solution for disposing of construction debris, enhancing productivity and safety on job sites.

Enhancing Workflow

At the core of efficient waste disposal lies the utilization of stainless steel construction debris chute process. These meticulously engineered systems streamline the removal of construction waste, providing a reliable pathway from upper floors to ground level. Their robust construction ensures longevity, while their sleek design facilitates smooth operation, minimizing downtime and maximizing productivity.

Navigating the Landscape

Central to the effectiveness of trash chutes are their individual components, including chute sections crafted from durable materials such as stainless steel or high-density plastic. The careful consideration of factors like cart edge length and diameter ensures optimal performance, while innovative features such as floor debris chutes and durachute roof products offer versatility in disposal methods, catering to the diverse needs of construction projects.

Commitment to Quality

In the competitive market of waste management solutions, Trash chute stands as a beacon of quality and innovation. Their commitment to excellence is reflected in the durability and reliability of their products, ensuring uninterrupted operation throughout the project lifecycle. From bottom renovation options to top-of-the-line roof chutes, Trash chute sets the standard for efficiency and performance in relics disposal.

Maximizing Utility

While primarily associated with construction projects, slops chutes find utility in a myriad of settings. From renovation endeavors to demolition sites, their versatility makes them indispensable tools for waste management. Moreover, their ease of use and efficiency outshine alternatives such as manual removal or traditional dumpsters, offering a superior solution for disposing of construction debris.Overcoming Obstacles

Despite their myriad benefits, trash chutes may encounter challenges such as debris blockages or size limitations. However, proactive maintenance and adherence to safety protocols mitigate these issues effectively, ensuring uninterrupted operation. Feedback and insights from users further inform improvements, driving innovation and refinement in rubbish chute systems to meet the evolving needs of the construction industry.

Types of Trash Chutes

Steel Construction Debris Chutes

Steel construction debris chutes are the most common type of trash chute used on job sites. These chutes are known for their strength and durability, making them ideal for heavy-duty relics disposal.

Plastic Chutes

Plastic chutes are a lightweight and cost-effective alternative to steel chutes. They are ideal for smaller construction projects or temporary use on job sites.

Durachute Chute Systems

Durachute process are a popular choice among demo contractors who need high-quality chutes for construction debris removal, thanks to their durability and long-lasting design.

Compactor Chutes

Compactor chutes are designed to handle large volumes of waste, making them ideal for buildings with high occupancy rates. These chutes utilize a compactor system that compresses the waste, allowing for more efficient disposal. Compactor chutes are commonly found in high-rise residential buildings, hotels, and commercial complexes.Recycling Chutes

Recycling chutes are specially designed for the collection of recyclable materials such as paper, plastic, glass, and metal. These chutes help promote sustainability and environmental conservation by providing a separate disposal system for recyclables. Recycling chutes are becoming increasingly popular in green buildings and communities that prioritize recycling initiatives.

Trash Chute Systems vs. Alternative Waste Removal Methods

In a world where convenience and efficiency are highly valued, garbage chute process have become a popular choice for waste removal in many buildings. However, are these systems truly the best option, or are there alternative methods that might be more beneficial in the long run? Let’s take a closer look at the pros and cons of trash chute method compared to other waste removal methods.

Trash Chute Systems

Trash chute process consist of a series of interconnected vertical chutes that allow residents or workers in a building to conveniently dispose of their trash on each floor. The trash then falls directly into a dumpster or compactor at the base of the building, eliminating the need for individuals to carry their waste to a central location.

Pros:

- Convenience: One of the biggest advantages of garbage chute methods is the convenience they offer. Residents or workers can simply toss their trash down the chute without having to make multiple trips to a central dumpster or compactor.

- Space-Saving: Garbage chute methods can help save space, as there is no need for bulky trash cans or dumpsters on each floor of a building.

- Hygiene: Trash chute process can help maintain hygiene in a building by reducing the chances of pests or odors spreading from trash cans.

Cons:

- Maintenance: Trash chute methods require regular maintenance to ensure they are functioning properly. Debris can get stuck in the chutes, leading to clogs and unpleasant odors.

- Safety Concerns: There is a risk of items getting stuck or causing a blockage in the chute, which can be a safety hazard.

- Limited Recycling: Garbage chute methods are typically used for general waste, and residents may need to make additional efforts to recycle their items.

Alternative Waste Removal Methods

While trash chute systems offer convenience, there are alternative waste removal methods that may be more suitable for certain environments.

Recycling Centers:

- Recycling centers provide a designated space for individuals to separate and dispose of their recyclable items. This method promotes sustainability and reduces the amount of waste that ends up in landfills.

Portable Trash Compactors:

- Portable trash compactors can be a great alternative for buildings or areas with limited space. These compactors can be easily moved to different locations and are designed to efficiently compress waste, reducing the frequency of trash pickups.

Waste Management Services:

- Hiring a waste management service can be a cost-effective and environmentally friendly option for waste removal. These services typically provide recycling solutions and can help businesses and buildings implement sustainable waste management practices.

VITAL ROLE OF TRASH CHUTES IN CONSTRUCTION: ENHANCING CREW BUILDING AND SAFETY

Efficiency and safety are essential in the fast-paced world of construction. Among the numerous tools and systems employed on-site, garbage chutes stand out as indispensable assets, particularly in streamlining debris disposal processes. From coordinating crew building activities to ensuring utmost safety, the integration of trash chutes into construction workflows proves instrumental. Let’s delve into how trash chutes significantly contribute to crew building and safety measures on construction sites.

Coordinating Crew Building Around Chute Usage

Efficient coordination of crew activities is paramount for the seamless progress of construction projects. Garbage chutes play a pivotal role in facilitating this coordination by providing a designated and safe pathway for debris removal. By strategically placing trash chutes throughout the site, construction crews can optimize their workflow, minimizing downtime caused by navigating through cluttered work areas or transporting debris manually.Ensuring On-site Safety Best Practices

Safety remains a paramount concern in the construction industry, and trash chutes serve as an essential component in upholding rigorous safety standards. Implementing best practices for chute usage significantly reduces the risk of accidents and injuries on construction sites. Proper installation, maintenance, and supervision of trash chutes are imperative to ensure their optimal functionality and safety.Working on rooftops presents inherent risks, including the potential for falls, material handling accidents, and debris accumulation. Incorporating a secure garbage chute method mitigates these risks by providing a safe and efficient means of disposing of debris directly from the rooftop to ground level. This eliminates the need for manual handling or transporting debris through stairwells or elevators, reducing the likelihood of accidents and minimizing disruption to other construction activities.

Durability and Reliability Factors for Chutes on Roofs workGiven the demanding conditions of rooftop environments, durability and reliability are paramount considerations when selecting garbage chute systems. Chutes installed on roofs must withstand exposure to varying weather conditions, heavy loads, and frequent use without compromising performance. Investing in high-quality chute process engineered for durability ensures long-term functionality and minimizes the need for costly repairs or replacements.

Debris Disposal Options Using Trash Chutes: Introducing Duraflat Floor Chutes

Debris disposal is a fundamental aspect of construction site management, with various options available to facilitate efficient waste removal. Among these options, Duraflat floor debris chutes stand out for their innovative design, durability, and advantages in streamlining debris disposal processes. Let’s delve into the diverse options for debris disposal using trash chutes and explore the unique features and benefits of Duraflat floor debris chutes.

Debris Disposal Options Using Trash Chutes

Trash chutes offer versatility in ruins disposal, catering to diverse construction site requirements and constraints. Whether for high-rise buildings, renovation projects, or industrial sites, there are several types of garbage chutes available to suit specific needs. From standard vertical chutes to angled or telescopic chutes, construction teams can select the most suitable option based on site layout, height, and volume of debris generated.

Duraflat Floor Debris Chutes

Duraflat floor debris chutes offer a cutting-edge solution for ruins disposal, combining innovative design features with robust construction to deliver superior performance on construction sites. Unlike traditional vertical chutes, Duraflat chutes feature a flat-bottom design, allowing for seamless placement on floors or scaffolding systems. This versatility enables convenient access to multiple levels of a building or construction site, eliminating the need for extensive structural modifications.

Versatility and Efficiency of Trash Chutes in Construction Sites

Debris disposal is a fundamental aspect of construction site management, with various options available to facilitate efficient waste removal. Among these options, Duraflat floor debris chutes stand out for their innovative design, durability, and advantages in streamlining debris disposal processes. Let’s delve into the diverse options for debris disposal using trash chutes and explore the unique features and benefits of Duraflat floor debris chutes.

In the dynamic realm of construction, efficient debris management is essential for maintaining a safe and organized work environment. Among the array of tools and technologies employed on job sites, debris chutes emerge as invaluable assets, facilitating the swift and secure disposal of waste materials. Let’s explore the significance of debris chute methods in optimizing work location operations and enhancing overall efficiency.

Enhancing Work Site Efficiency with Debris Chute SystemsThe bustling activity on a construction site generates a substantial amount of debris, ranging from rubble and scrap materials to packaging and discarded equipment. Managing this debris efficiently is crucial for maintaining a clean and hazard-free work environment. Debris chute systems provide a systematic solution for expediting the removal of waste materials from elevated areas to ground level, minimizing clutter and streamlining cleanup efforts.

By strategically installing debris chutes at various locations throughout the work site, construction crews can expedite the disposal process, eliminating the need for manual handling or transport of debris. This not only accelerates project timelines but also enhances overall productivity by allowing workers to focus their efforts on core construction tasks without disruptions caused by debris accumulation.

Stainless Steel Chute Sections: Durability and Reliability

The durability and reliability of debris chute process are paramount considerations in their selection and implementation. Stainless steel chute part offer unparalleled strength and resilience, making them ideal for use in demanding construction environments. Unlike traditional materials, such as plastic or galvanized steel, stainless steel provides superior corrosion resistance, ensuring longevity and performance in various weather conditions.

Additionally, stainless steel chute sections are easy to clean and maintain, minimizing the risk of contamination or obstruction that could impede debris flow. Their robust construction allows them to withstand heavy loads and abrasive materials, making them suitable for use in both commercial and residential construction projects. By investing in stainless steel chute sections, construction professionals can ensure the long-term reliability and effectiveness of their debris management systems.

Optimizing Trash Removal on Job Sites

Efficient trash removal is essential for maintaining a clean and organized job site, enhancing safety and productivity. Debris chute methods play a pivotal role in optimizing trash removal processes by providing a convenient and effective means of disposing of waste materials. Whether used for construction debris, packaging, or general trash, chute methods streamline the removal process, reducing manual labor and minimizing the risk of accidents or injuries.

By integrating debris chutes into their waste management protocols, construction teams can improve overall site cleanliness and efficiency, leading to smoother project workflows and timely completion. Furthermore, the use of debris chute methods demonstrates a commitment to environmental responsibility by facilitating proper waste disposal practices and minimizing the impact of construction activities on the surrounding area.